We feel the pleasure to introduce our HTV silicone rubber for extrusion, it’s recommended the TBL-500A series , with good tear strength, stable and reliable product quality. The hardness of precipitation and fumed 40-80 hardness can be for extrusion with good production speed. If the customer has problems during production, we need to match the vulcanizing agent.

TBL, provide the best and professional silicone rubber raw material solution!

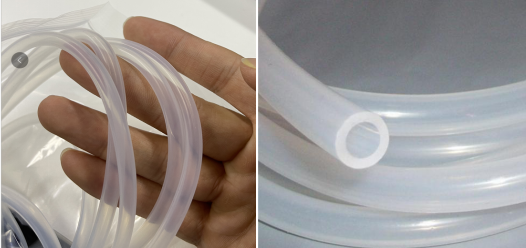

Applicable to: silicone products such as milk bottle silicone straw, silicone rubber tube, electric heating tube, heat-resistant seal, etc. For more purposes, you can customize it as needed.

What is the difference between molding compression HTV silicone rubber and extruded HTV silicone rubber?

1. molding compression HTV silicone rubber is molded by vacuum machine, while extruded silica gel is extruded by extruder;

2. molding compression HTV silicone rubber is to add double 2,5 curing agent or odorless vulcanizing agent, which is applicable to silicone products,such as keyboards, seals, silicone rings, gaskets and other industrial parts.

The HTV silicone rubber for extrusion is to add double 2,4 curing agent or platinum curing agent. It is suitable for all kinds of wires, cables, hoses and silicone strips, etc.

There are great differences between the two curing agents and can not be mixed;

3. Both molding compression silicone rubber and extruded silicone rubber can reach food grade. Tasteless curing agent must be added when molded silicon reaches food grade, while platinum curing agent must be added when extruded silicon reaches food grade;

4. The molding time of molded silicon is 60s-180s, and the molding time of extruded silicone is only a few seconds;

5. The molded silicone is limited by the size of the product mold, and the size and specification of the formed product are limited. However, the extruded silicon is produced through the extrusion process, and the formed product can be produced without restriction all the time;

- The silicon rubber mixing is uneven and the operator is not standard.

- The rubber has moisture.

- The vulcanized molding is not sufficient, and there are bubbles when it is not ripe.

- There are many impurities in the vulcanizing agent, the impurities of small molecules become differentiated early, and bubbles remain in the products.