TBL Silicones understands how important performance and processability is when producing high quality precision molded parts for the medical grade products. Liquid Silicone Rubbers (LSR) are typically used with injection molding machines, enabling consistent production of reproducible silicone parts with optimum quality, excellent process control and minimum cost. The material is delivered as a two-part product, where the A part contains the catalyst (platinum) and the B part contains the cross-linker. Both parts are pumped and mixed, metered into the injection unit, the vulcanized under heat and pressure in the mold.

Our medical grade liquid silicone rubber LSR TBL-8880 offer distinctive advantages for producing high quality precision molded parts for the medical grade products, including easy processing, easy release and high-performance physical properties to improve part appearance, functionality, and productivity.

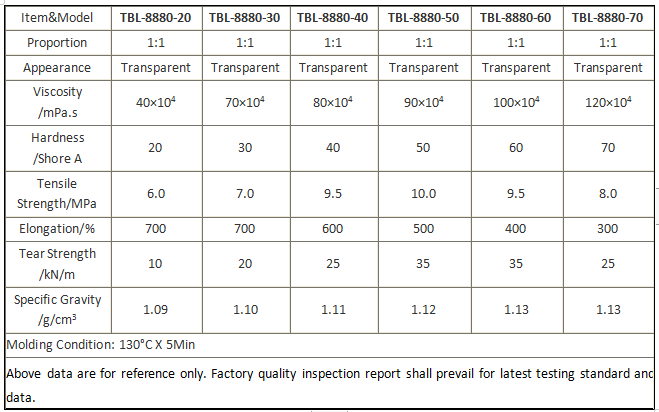

TBL-8880 Series Medical Grade Liquid Silicone Rubber

Product Description:

TBL-8880 series is two-component additive molding series liquid silicone rubber. It has fast solidification and molding speed in high temperature and adopts the liquid injection molding process technology.

The product conforms to ISO10993 Bio-compatibility requests. It can be widely used in manufacturing of medical grade products, such as medical catheter, negative pressure ball, laryngeal masks,etc.

Product Features :

- Formulated to meet the requirements of Bio-compatibility

- High Transparency

- High Strength

- Good yellowing resistance

- Rapid prototyping

Main Technical Parameters:

How To Use:

1. Suggest that the consumer use the LSR for injection molding machine to inject into the mold and manufacture products.

2.The two components of A and B must be completely mixed by machine according to the weight or volume ratio of 1:1. The vulcanization time is determined by the molding temperature. At high temperature conditions, a short time is required for product forming. If the silicone product is thick and large, it takes longer time to mold.

TBL Silicone are ISO 14001 certified, and our TBL-8880 Liquid silicone rubber LSR medical grade is biocompatibility comply: