Application of TBL Silicone Rubber for Auto Parts And Kitchenware

- By:tblsilicone

- Date:2021/08/22

Silicone material is more and more popular, it has been used to varies areas because of it is good workability, easy stripping, tear strength, eco-friendly and non-toxic. Today we would like to introduce the silicone material-silicone rubber, which is used for auto parts and kitchenware.

Silicone rubber for auto parts:

The automotive industry, which currently produces up to 80 million vehicles per year, is constantly innovating and demanding new high-performance applications, both under the hood and elsewhere in the car. These new advanced automotive parts are often designed to reduce weight and fuel consumption, thereby leading to smaller and more compact engine compartments, resulting in higher temperatures and more stress to vital parts because of higher air pressure, greater water flow, more powerful fuel injection and corrosive fluids.

TBL silicones high-quality HCR (High Consistency Rubber) silicones, for their part, can withstand extreme temperatures of up to 250°C, because of their stability, and are therefore ideal for a wide range of critical parts. Advanced silicones for automotive applications are designed to achieve the best balance between tear resistance and compression set at high temperatures. Furthermore, these advanced silicone products are easy to use in a wide range of processes, such as extrusion, calendering or injection molding, in line with customers’ industrial setups.

TBL Silicone HCR formulations are perfectly adapted to these applications, because they offer the following features:

Silicone rubber for kitchenware:

For kitchenware products need use food grade silicone rubber, TBL silicone HCR/HTV/LSR silicone rubber has food grade silicone rubber.

Food grade silicones are increasingly the material of choice for the entire food processing cycle, from large-scale industrial facilities and restaurants to home cooking, as well as in food packaging and labelling. They are convenient, safe, heat resistant, long-lasting, versatile and ensure no modification of food properties and tastes when in contact with food.

What are the main applications of silicone-based kitchenware products?

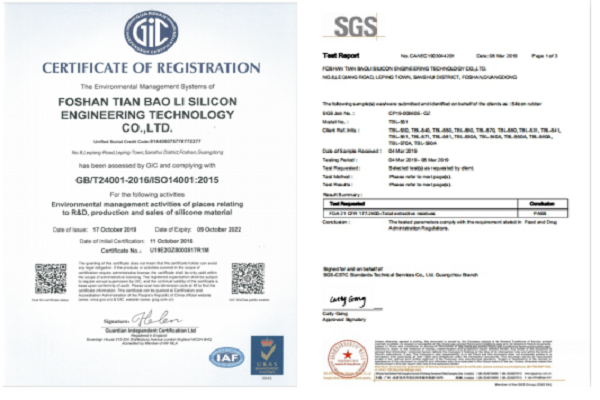

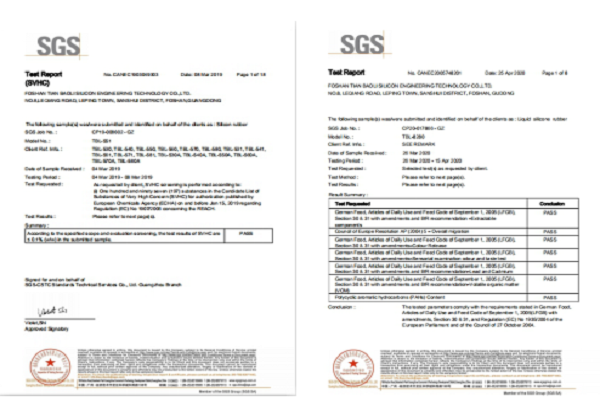

Finally, TBL Silicones food grade silicone rubber products are ISO 14001 certified for biocompatibility and compliant with the highest national and international regulatory and quality requirements, including approval by the US FDA, the European Union regulation concerning the Registration LFGB, Evaluation, Authorization and Restriction of Chemicals (REACH), the German Food, Articles of Daily Use and Feed Code, etc.

CONTACT US

Foshan Tian Bao Li Silicon Engineering Technology Co., Ltd.

We are always providing our customers with reliable products and considerate services.

If you would like to keep touch with us directly, please go to contact us