Foshan Tian Bao Li Silicon Engineering Co., LTD is a professional FDA HTV silicone rubber and FDA liquid silicone rubber factory. TBL silicone is the brand of Foshan Tian Bao Li Silicon Engineering Co., LTD . TBL silicone is specialized in the research, development, production, and sales of FDA silicone rubber and FDA liquid silicone rubber ,we own the only FDA silicone rubber automatic production lines and various advanced silicone rubber production equipments in China ,The annual design production capacity is more than 30000 tons. FDA HTV Silicone rubber and FDA liquid Silicone rubber of the most important parts of silicones. Because of its excellent characters such as high and low temperature resistance, electrical properties, high transparency, Excellent processing property , Tear strength , Easy to demould, weathering and age resistance, physiological inertness, it is widely used in Kitchenware products .

First、FDA High Temperature Vulcanized Silicone Rubber (FDA silicone rubber ):

1. Precipitation FDA High Temperature Vulcanized Silicone Rubber ( FDA HTV Silicone rubber ) , It is mainly produced by Na2SiO3 solution precipitated by SiO2 to produce coarse particles, which will turn white when stretched, and the appearance is translucent. The cost of raw materials is relatively cheap and the price is cheap. The market calls this: precipitated silicone rubber .Show the models of our factory:TBL-500A,has 30,40,50,60,70,80Hardness .FDA silicone rubber and FDA liquid silicone rubber have Certificates: ISO, REACH, ROHS, LFGB, UL&FDA certificated .

2. Fumed FDA HTV Silicone rubber , mainly produced by the mixed combustion of SiCl4 and H2 and O2 to produce fine particles, which will not turn white when stretched, and can be stretched longer without breaking. The appearance is transparent, the cost of raw materials is high, and the price is high , generally used for products with high requirements, so the cost is higher,The market calls this: fumed silicone rubber .Show the models of our factory:TBL-900 and has 20,30,40,50,60,70Hardness .FDA silicone rubber and FDA liquid silicone rubber have Certificates: ISO, REACH, ROHS, LFGB, UL&FDA certificated.

Second、There are two different forming ways of FDA HTV silicone rubber :

1. Molding

Definition: Molding molding, also known as pressing molding, is the mixture of good rubber material in the mold cavity, with the help of pressure and heat, so that the material is filled with the mold cavity, the formation of the same products with the mold cavity, and then after heating to solidify the demoulding, its molding products is molded products.It is suitable for FDA Silicone Rubber

2. Extrusion molding

Definition: extrusion forming in rubber processing is the process of making various continuous products by a single screw extrusion mechanism.Such as pipes, sealing strips, wire and cable cladding.It is suitable for Food Grade FDA Silicone Rubber.

Third、When using FDA HTV Silicone rubber ( FDA Silicone rubber) , Curing Agent must be added

Different processes have different Curing Agent :

- Molding : can only be used for molded Curing Agent: 2,5-Dimethyl-2,5-di(tert-butylperoxy)hexane, abbreviation: DMDBH or double-2,5 ,It must be added

- Extrusion molding: can only be used for Extrusion Curing Agent: 2,4-dichlorobenzoyl) peroxide, abbreviated as: DCBP Or double-2,4 ,It must be added.

Fourth、FDA Silicone rubber Packaging : standard export package,20 kgs per carton

Fifth、Certificate :

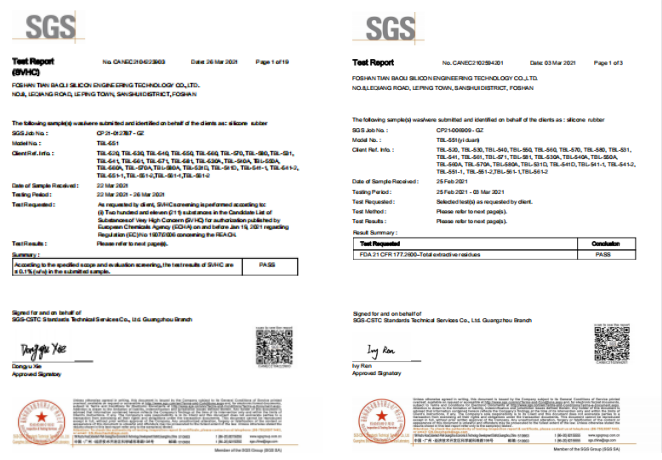

Both FDA HTV Silicone rubber and FDA liquid silicone rubber have passed the following certifications: ISO, REACH, ROHS, LFGB, UL&FDA certificated .