Foshan Tian Bao Li Silicon Engineering Co., LTD are a professional medical grade silicone rubber raw materials factory ,and is a medical silicone rubber supplier. Besides, Medical grade silicone rubber raw materials is one of the largest sectors of the global economy.

Medical grade silicone rubber raw materials Description:

Medical grade silicone rubber raw material is great for both indoor and outdoor use. The molding of LSR is able to protect every piece of a device, from gaskets and buttons to keypads and plugs. With a portable medical appliance like a home blood pressure checking machine, medical liquid injection molding can be applied to anything from tubing to connective pieces.

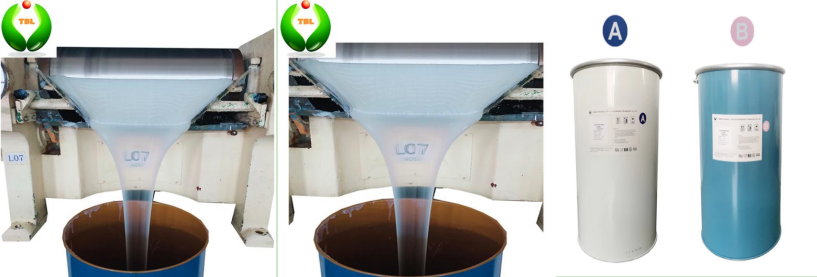

Transparent silicone for medical products is two-component additive molding series liquid silicone rubber. This product is composed of two components A and B. The two components A and B must be completely mixed according to the weight or volume ratio of 1:1, component A contains catalyst and component B contains cross-linking agent. It has fast solidification and molding speed in high temperature and adopts the liquid injection molding process technology. This product conforms to ISO10993 Bio-compatibility requests. It can be widely used in manufacturing of medical grade products, such as medical catheter, negative pressure ball, laryngeal masks,etc.

Transparent silicone for medical products , it is a distinct honor to provide liquid silicone rubber (LSR) to the medical industry, because we know how important it is to put functioning, durable solutions in the hands of medical professionals. Our medical grade liquid silicone rubber TBL-8880 pass the certifications of Biocompatibility request, LFGB, FDA, ROHS, REACH, We are a professional medical silicone rubber supplier.Show the models of our HTV silicone rubber factory:TBL-8880-20(has 20,30,40,50,60,70Hardness)

Transparent silicone for medical Products Features:

- Conform to Bio-compatibility Certification

- High Transparency

- High Strength

- Good yellowing resistance

- Rapid prototyping

- professional medical silicone rubber supplier manufacturing

How to use Transparent silicone for medical prodcts:

1. Suggest that the consumer use the liquid injection molding machine to inject into the mold and manufacture products.

2. The vulcanization time is determined by the molding temperature. At high temperature conditions, a short time is required for product forming. If the silicone product is thick and large, it takes longer time to mold. After vulcanization, the mold can be disassembled.this is transparent silicone for medical products .

3. If the machine is shut down for a long time (more than two days), either inject component A or component B into the mixing section alone. Or remove the static mixer of the injection molding machine immediately, seal and store it in a low temperature (< 1℃) environment, or clean up the remaining rubber.

Medical silicone rubber supplier Packaging, Storage and Caution :

1. This series of product is packed in 20 kg/plastic straight pail or 200 kg/metal drum, with plastic liners.

2. Products should be stored in sealed condition, kept it in a cool place and avoid rain and sun exposure.

3. Transparent silicone for medical products are non-dangerous goods. The valid period is 1 year. If the products exceed the storage life, it can be re-tested to prove the curing speed is acceptable, if so, it can be used.

4. /To prevent cure inhibition, try to avoid contact with tin compound (most condensation silicone contain tin compound catalyst) amines, sulfur and phosphorus compounds and some metal salts.

5. When products from different Medical grade silicone rubber raw materials factory are used, tests shall be carried out to avoid cross-linking reaction."TBL" is on the label of Medical silicone rubber supplier.