Introduction of HTV Silicone Rubber

- By:

- Date:2021/06/28

Common silicone rubber can be divided into two broad categories:

1, precipitation high temperature vulcanized silicone rubber (PPT silicone) TBL-500A, TBL-500, TBL-501

2, Fumed high temperature vulcanized silicone rubber (FUMED silicone) TBL-900

The white carbon black used by the two is not the same, the white carbon black particle size of the gas phase adhesive is small, the specific surface area is played, the surface adsorption force is strong, the dispersion is good, has superior stability, reinforcement, thickening, and purity, generally used for products with high requirements, so the cost is higher.

The silica particle size of precipitated adhesive is large, generally sub-micron, with small specific surface area, high water content and electrolyte content, and its reinforcing performance is lower than that of gaseous silica, especially its tear resistance. Advantage is added to the silicon rubber thickening is small, and because its single particle does not deform, so it is suitable for the preparation of low compression permanent deformation and high resilience products

There are two different forming ways of high temperature rubber:

1, molding

Definition: Molding molding, also known as pressing molding, is the mixture of good rubber material in the mold cavity, with the help of pressure and heat, so that the material is filled with the mold cavity, the formation of the same products with the mold cavity, and then after heating to solidify the demoulding, its molding products is molded products.

2, extrusion molding

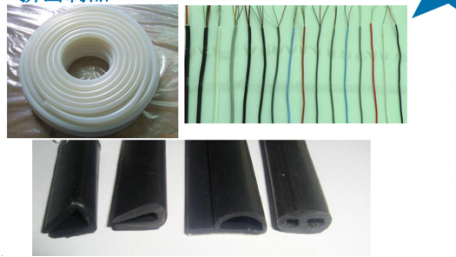

Definition: extrusion forming in rubber processing is the process of making various continuous products by a single screw extrusion mechanism. Such as pipes, sealing strips, wire and cable cladding.

Today I will recommend HTV silicone rubber that can be used in both molding & extrusion:

TBL-500A(PPT) TBL-900(FUMED),

TBL-500A hardness range of this series of products is 30-80A, with good heat resistance, high transparency, good processability, easy demoulding, high tear strength characteristics.

If the food grade requirement is higher, I recommend TBL-900. Better transparency, higher intensity. It is widely used in automobile and medical fields

You can decide which model to use according to your product requirements.

CONTACT US

Foshan Tian Bao Li Silicon Engineering Technology Co., Ltd.

We are always providing our customers with reliable products and considerate services.

If you would like to keep touch with us directly, please go to contact us