1. High temperature vulcanized silicone rubber(HTV Compound)

HTV Silicone Rubber is a polyorganosiloxane (raw rubber) with high molecular weight (generally 400,000-800,000) with reinforcing fillers and various other additives. Using organic peroxide as vulcanizing agent, it is molded under pressure (molding, extrusion), and cross-linked at high temperature to form rubber, which is referred to as HTV silicone rubber materials for short.

The vulcanization process of high temperature vulcanized silicone rubber is divided into two stages. The first stage is to put the mixed silicone rubber into a metal mold for heat forming and vulcanization. Under the condition of pressure of 10MPa, temperature of 165-170 degrees Celsius, hot pressing for 15-20 minutes. The second stage is to take the silicone rubber materials out of the mold, put it in a blast oven, and bake it at 200-250 degrees Celsius for 4 hours to further vulcanize the silicone rubber and decompose and volatilize the organic peroxide.

2. The composition system of HTV compound

To prepare silicone rubber materials, in addition to raw rubber, there are many other additives. Such as reinforcing agent, structure control agent, anti-tear agent, cross-linking agent, catalyst. If HTV compound is used to make finished products, vulcanizing agents and pigments added as needed must also be used.

3. Processing of high temperature silicone rubber materials

Open mill mixing is the most traditional mixing method in the silicone rubber processing industry. Due to its great flexibility, the specific mixing situation can be observed carefully during the rubber mixing process, which is especially suitable for small-scale, small-batch, and multi-variety production. Large-scale production is carried out in kneaders or closed mixing equipment.

When mixing silicone rubber materials, the proper order of addition will help the uniformity of the compound. If the feeding sequence is not appropriate, it will affect the uniformity of the additive dispersion, and even lead to roll off, over-training, or scorching. The mixing time is generally 20-30 minutes, and the special effect silicone rubber material can be more than 40 minutes. The speed of the mill is generally controlled at 16-18 r/min.

4. Test method of high temperature vulcanized silicone rubber

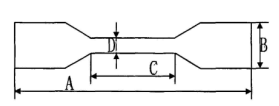

As shown in the shape on the picture, it is a thin sheet of high-temperature silicone rubber after secondary vulcanization.

Size A:110mm, B:25mm±1, C:33mm±2, D:6mm±0.4, Thickness:2mm±0.30

The thin section tested for tensile properties is a dumbbell-shaped specimen.

Test the mechanical properties with Testometric M350-20KN electronic tensile machine.Place the sample in the center of the holder, start the machine, stretch the sample at a speed of 500 mm/min, and track the mark of the working part of the sample through the test pointer. Record the data values of the load, elongation and breaking strength when the sample breaks, and obtain the stress-strain curve.

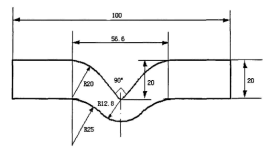

According to the requirements of GB288-82, tear strength test sample pieces pattern above.

High temperature vulcanized silicone rubber is a kind of special rubber with excellent performance. The test results are different and can vary depending on various factors, such as raw materials, mixing methods and the ratio of other additives.