- Home

- Product

- RTV Silicone Sealant & Adhesive

- Thermal Potting Silicone Sealant TBL-6733

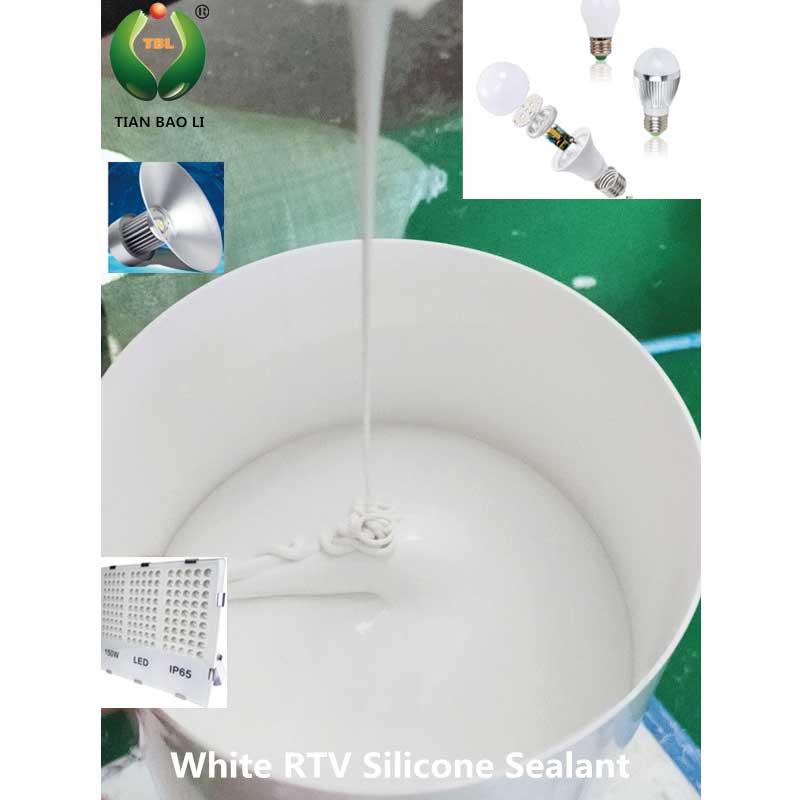

Thermal Potting Silicone Sealant TBL-6733

- Model: TBL-6733

PRODUCT Description

Technical Parameter

Two component RTV silicone adhesive, dealcoholized1 to 1 condensed type curing, white/black paste. Fast curing at room temperature. Cure to a tough, flexible rubber.

Product Features

Excellent adhesion to various substrates.

No corrosion to substrates.

Excellent dielectric properties.

Excellent weather fastness.

Complies with EU ROHS.

Stable and flexible from -40℃ to+180℃.

Typical Applications

Various home appliance panels, brackets, pendants bonding, such as microwave oven induction cooker brackets bonding.

mica plate, collar bonding;

Solar backplane and glass bonding;

Note

In the process of storage, the sealant may be a small amount of solidification or oil-penetration at the nozzle, which can be used normally after removal without affecting the product properties. Double-tube packaging squeeze a small amount of sealant at the same time before components A and B to eliminate air bubbles in the head, and then connect the mixing tube.

Operating Instructions

Clean surface: Please clean up the dust, rust, and oil

on the surface of the bonding substrate.

Mixture ratio: Mix according to the weight ratio of 1 to 1. If you need to change the ratio, it should be applied after the test.

Gluing: Squeeze the sealant onto the cleaned surface.

Curing: Place the glued part in the air for natural curing. The higher the temperature of the environment, the shorter of working and curing time. But can’t heat curing, otherwise, will have air bubbles inside the sealant, which will affect the bonding and sealing effect.

Storage: The unused sealant should be immediately tightened and sealed. Before using again, may be a small amount of solidification at the nozzle, which can be used normally after removal without affecting the product properties.

Storage conditions

Store in a cool and dry place below 35 ℃.

Shelf life: 6 months.

Attentions

1. Keep away from children.

2. It is recommended to use it in a well-ventilated area to reduce odor.

3. If accidentally touch the skin or eyes, wipe them clean immediately, then rinse with water and seek medical advice.

4. For safety information, please refer to the Material Safety Data Sheet (MSDS).

Packaging specifications

2600ml / piece, 4 pieces / Carton

Special Note

The data in this manual were obtained under laboratory conditions, due to differences in the use environment, users should refer to these data and conditions for analysis and testing. Tian Bao Li does not guarantee the sales of products and the use of Trimble products under specific operating conditions, and does not assume any liability for direct, indirect or accidental losses. If the user encounters any problems during use, you can contact the Tian Bao Li technical service department, we will provide you with the help.

|

Reference Standards |

Property |

Unit |

Value |

|

Properties before curing at 25±2℃ |

|||

|

GB/T 14074 |

Appearance (A) |

/ |

White/Black Paste |

|

GB/T 14074 |

Appearance (B) |

/ |

White/Black Paste |

|

GB/T 13354 |

Density (A) |

g/cm3 |

1.35±0.1 |

|

GB/T 13354 |

Density (B) |

g/cm3 |

1.35±0.1 |

|

GB/T 13477.5 |

Tack-free time |

min |

≤10 |

|

Enterprise Standard |

Initial curing time |

min |

≤30 |

|

Properties cured 7 days at 25±2℃ |

|||

|

GB/T 531.1 |

Hardness |

Shore A |

40 |

|

GB/T 528 |

Tensile Strength |

MPa |

1.80 |

|

GB/T 528 |

Elongation at break |

% |

150 |

|

GB/T7124 |

Shear Strength (AL/AL) |

Mpa |

1.50 |

|

GB/T 1695 |

Dielectric Strength |

kV/mm |

≥20 |

|

GB/T 1693 |

Dielectric Constant |

/ |

≥2.8 |

|

GB/T 1692 |

Volume Resistivity |

Ω·cm |

≥1×1014 |

|

Note: The latest version applies to this document. |

|||

Related Products

CONTACT US

Foshan Tian Bao Li Silicon Engineering Technology Co., Ltd.

We are always providing our customers with reliable products and considerate services.

If you would like to keep touch with us directly, please go to contact us