- Home

- Product

- RTV Silicone Sealant & Adhesive

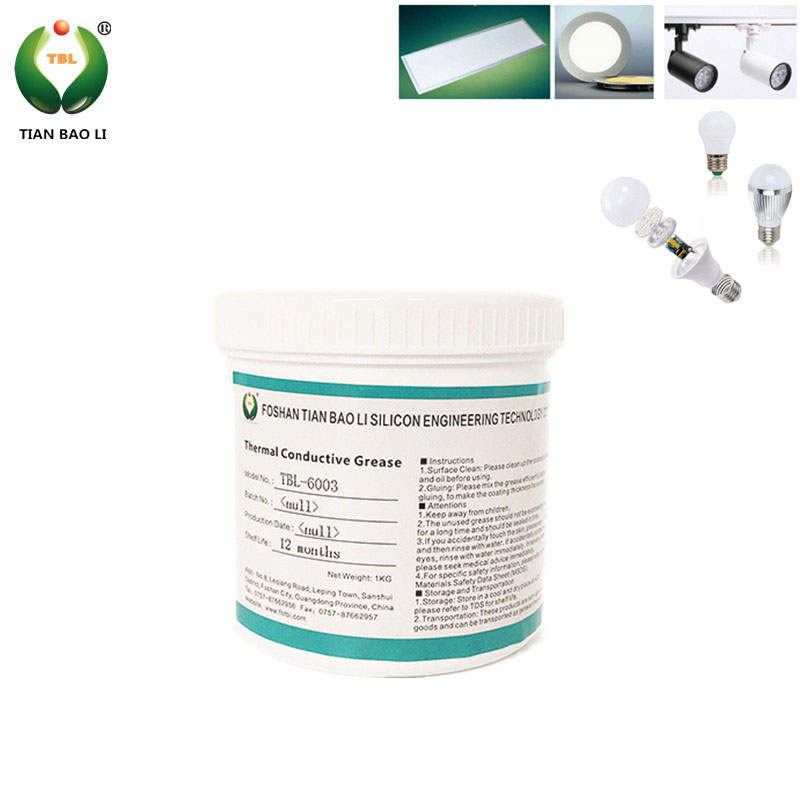

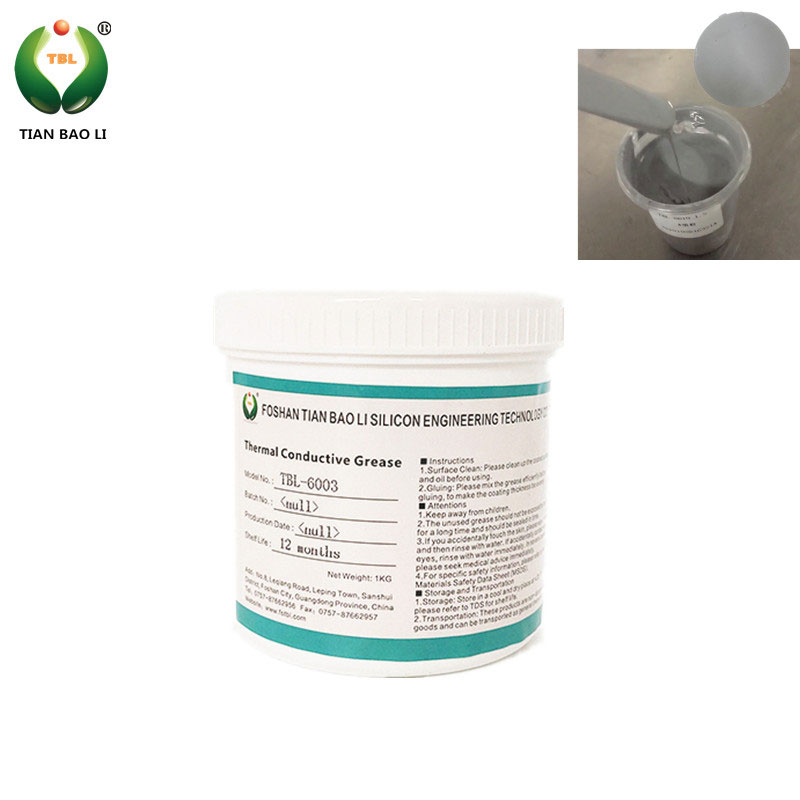

- Thermal Conductive Grease TBL-6003-1.0

Thermal Conductive Grease TBL-6003-1.0

- Model: TBL-6003-1.0

PRODUCT Description

Technical Parameter

TBL-6003-1.0 Heat Conduction Silicone Grease is based on polyorganosiloxane, and add the high thermal conductivity filler by special process compounded to make paste. As a medium for transferring heat, also have excellent thermal conductivity and electrical insulation. This product has good resistance to high and low temperature, will not appear air drying hardening or melting, non-toxic, tasteless and non-corrosive, chemical and physical properties are stable.Suitable for manual / machine operation

Product Features

Thermal Conductivity 1.0W/m.k Tasteless, non-corrosive, non-toxic, environmentally friendly Low thermal resistance, high temperature resistance non- powdering, good thermal conductivity Reduce the operating temperature of the heating element, high power bipolar junction transistor, filling the gap between the SCR (thyristor) Diode (transistor) and the substrate (aluminum, copper), CPU and radiator.

Typical Applications

CPU Heat Dissipation.

Aluminum Base Panel Heat Dissipation.

MOS Tube Heat Dissipation.

TV Power Amplifier Tube Heat Dissipation.

Note

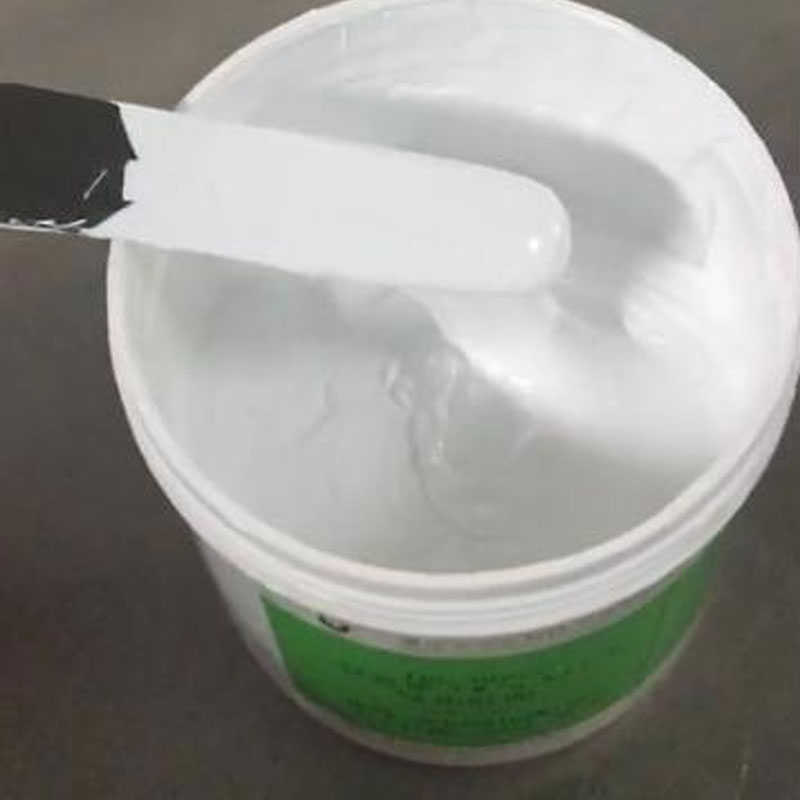

The sealant will be delaminated during storage, and it will be stirred evenly before mixing, which will not affect the properties of the product.

Operating Instructions

Preparation: It is recommended to pre-mix the product after it has been left for a long time before using it. When it needs to be applied to the material, please confirm with a sample before use, and then apply.

Cleaning the surface: Clean the surface to be coated before use to remove oil stains.

Gluing: For smoother gluing, it is recommended to stir for 2 minutes before gluing. The coated surface should be consistent, guaranteed fill the surface gap to coat a thin layer.

Storage: The product should not be exposed to the air for a long time.

Storage conditions

Store in a cool and dry place below 35 ℃.

Shelf life: 12 months.

Attentions

1.Keep away from children.

2.It is recommended to use it in a well-ventilated area to reduce odor.

3.If accidentally touch the skin or eyes, wipe them clean immediately, then rinse with water and seek medical advice.

4.For safety information, please refer to the Material Safety Data Sheet (MSDS).

Packaging specifications

1kg / piece, 12 pieces / Carton.

300ml / piece, 24 pieces / Carton.

2600ml / piece, 4 pieces / Carton.

Special Note

The data in this manual were obtained under laboratory conditions, due to differences in the use environment, users should refer to these data and conditions for analysis and testing. Tian Bao Li does not guarantee the sales of products and the use of Trimble products under specific operating conditions, and does not assume any liability for direct, indirect or accidental losses. If the user encounters any problems during use, you can contact the Tian Bao Li technical service department, we will provide you with the help.

|

Reference Standards |

Property |

Unit |

Value |

|

General Properties at 25±2℃ |

|||

|

GB/T 14074 |

Appearance |

/ |

White/Grey Paste |

|

GB/T 13354 |

Density |

g/cm3 |

2.50±0.1 |

|

ASTM D5470 |

Thermal Conductivity |

W/m.k |

≥1.0 |

|

GB/T 4509 |

Penetration Degree |

1/10cm |

≥300 |

|

GB/T 2793 |

Fugitive Constituent (150℃, 3h) |

% |

≤0.3 |

|

HG/T 2502 |

Oil Separation (200℃, 8h) |

% |

≤0.5 |

|

Enterprise Standard |

Working Temperature |

℃ |

-50~200 |

High resilience silicone rubber has many uses, such as making t-shirts for use in trade shows, making protective coatings for industrial equipment and so on. It is used in a wide variety of industries because it has a number of properties that make it highly resistant to wear and tear. Silicone is one of the strongest and most durable materials known to man. This is the reason why many manufacturers prefer to use it in their products.

High resistance means that the material will be able to withstand heat and pressure. In addition to this, it also has high elasticity, meaning that it can stretch to a large extent without ripping or tearing at all. The resistance to stress corrosion also makes it ideal for manufacturing purposes. It can handle high temperatures, which is great for industries requiring high quality parts that can stand up to extreme heat and corrosive chemicals. It also has a high amount of strength, which increases the likelihood that it will be able to carry out tasks that require force.

Flexible and high elasticity, silicone rubber can also easily be formed into sheets that have different thicknesses depending on their application. Its malleability makes it easy to bend it into the desired shape without much trouble. This property makes it ideal for making tubes, pipes and other similar objects. In fact, it is the ultimate material for bending and stretching. As it has high elasticity, it can readily conform to any shape without ripping or tearing.

Another important characteristic of high quality silicone rubber is its extreme durability. It is known to have high tensile strength that allows it to stand up to tremendous amounts of force. It is able to withstand pressure of up to 500 pounds per square inch, which makes it a suitable material for high pressure applications like industrial treadmills and industrial grinders.

The above characteristics of high resistant silicone rubber make it an integral part of many industries. They are ideal for use in a wide range of mechanical parts because of its high resistance to force and heat. Because of its unique properties, silicone rubber is often used as a building material in construction projects like roofs and flooring. In addition to that, it is also commonly used in automobile tires and other automotive parts because it is flexible, ductile and highly elastic. In the automotive industry, silicone rubber is used in air bags and other forms of packaging because it is flexible and ductile.

Related Products

CONTACT US

Foshan Tian Bao Li Silicon Engineering Technology Co., Ltd.

We are always providing our customers with reliable products and considerate services.

If you would like to keep touch with us directly, please go to contact us