- Home

- Product

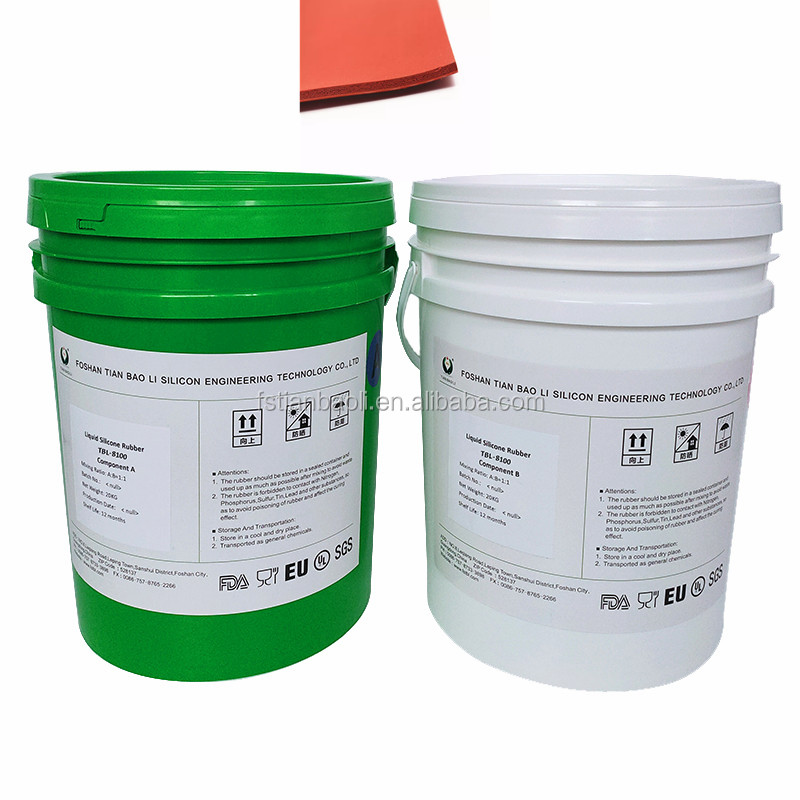

- RTV2 Mold Silicone Rubber

- RTV2 Two-component liquid silicone foam-TBL-8500 Series

RTV2 Two-component liquid silicone foam-TBL-8500 Series

- Place of Origin: Guangdong, China

- Brand Name: TBL

- Model Number: TBL-85 series

- MOQ:200KG

- Payments: TT, LC at sight

- Shipper terms: EXW, FOB, CIF

- Lead Time: 7-10days

PRODUCT Description

TBL-85 series is a two-component medium and low temperature vulcanized liquid foaming silicone. After the two components are mixed, the viscosity is moderate, the curing time is short, and no pollutants are released during the curing process. It is suitable for molding and calendering.

•The foamed silica gel sheet is prepared by the calendering foaming process, which is used in the new energy vehicle to play the role of shock absorption and sealing

•Silicone chest pads, shoulder pads, non-slip pads, foam silicone dolls, etc.

• Foamed silicone sealing strips, sealing rings, etc.

|

Model |

Color |

Hardness/ shore00 |

Density/ g/cm3 |

Mixing Ratio |

Operating Time/min, 25℃ |

Foaming Time/min, 60-80℃ |

Retardant Flame Grade |

Viscosity/ mpa.s |

|

TBL-8520 |

Transparent |

20-40 |

0.2-0.3 |

1:1 |

5-20 (Adjustable) |

15-30 |

Not flame retardant |

2w-5w |

|

TBL-8530 |

Transparent |

20-40 |

0.3-0.4 |

1:1 |

5-20 (Adjustable) |

15-30 |

Not flame retardant |

2w-5w |

|

TBL-8540 |

Transparent |

20-40 |

0.4-0.5 |

1:1 |

5-20 (Adjustable) |

15-30 |

Not flame retardant |

2w-5w |

|

TBL-8520-ZR |

Grey |

20-40 |

0.2-0.3 |

1:1 |

5-20 (Adjustable) |

15-30 |

FV-0 |

2w-5w |

|

TBL-8530-ZR |

Grey |

20-40 |

0.3-0.4 |

1:1 |

5-20 (Adjustable) |

15-30 |

FV-0 |

2w-5w |

|

TBL-8540-ZR |

Grey |

20-40 |

0.4-0.5 |

1:1 |

5-20 (Adjustable) |

15-30 |

FV-0 |

2w-5w |

|

• Delicate and evenly foamed pores • Excellent tear strength • Low water absorption • Operating temperature -50℃~200℃ • Platinum vulcanization is environmentally friendly and non-toxic •Closed-cell foam, good rebound, small compression set |

Instructions:

• Manual operation: Prepare the materials of components A and B, accurately weigh the two components A and B with a mass ratio or volume ratio of 1:1, stir the A and B components evenly by hand or machine, and then pour them into the In the molding die, heating and foaming molding.

•Machine operation: put the A and B components into the A and B cylinders of the two-component filling machine respectively, and then adjust the machine parameters to ensure the quality of the A and B components discharged from the machine or The volume ratio is 1:1, then start the machine, mix components A and B to the mixing head and stir evenly, inject them into the calendering foam silicone line, and enter the drying tunnel at 60-80 °C for foaming.

Precautions

This product is an addition type silicone rubber with platinum vulcanization system. The following substances will affect or hinder the curing of the product:

• Compounds containing heavy metal ions such as tin (Sn2+), lead (Pb2+), mercury (Hg2+);

•Organotin and silicone glue containing organotin;

• Organic compounds containing N, S, P;

• Certain unsaturated hydrocarbon plasticizers, etc.

Packaging Specifications

20kg/drum, 40kg/Pair. 200kg/drum, 400kg/Pair

Storage

Store in a sealed container below 25°C. The validity period of components A and B is twelve months from the date of manufacture.

Related Products

CONTACT US

Foshan Tian Bao Li Silicon Engineering Technology Co., Ltd.

We are always providing our customers with reliable products and considerate services.

If you would like to keep touch with us directly, please go to contact us