- Home

- Product

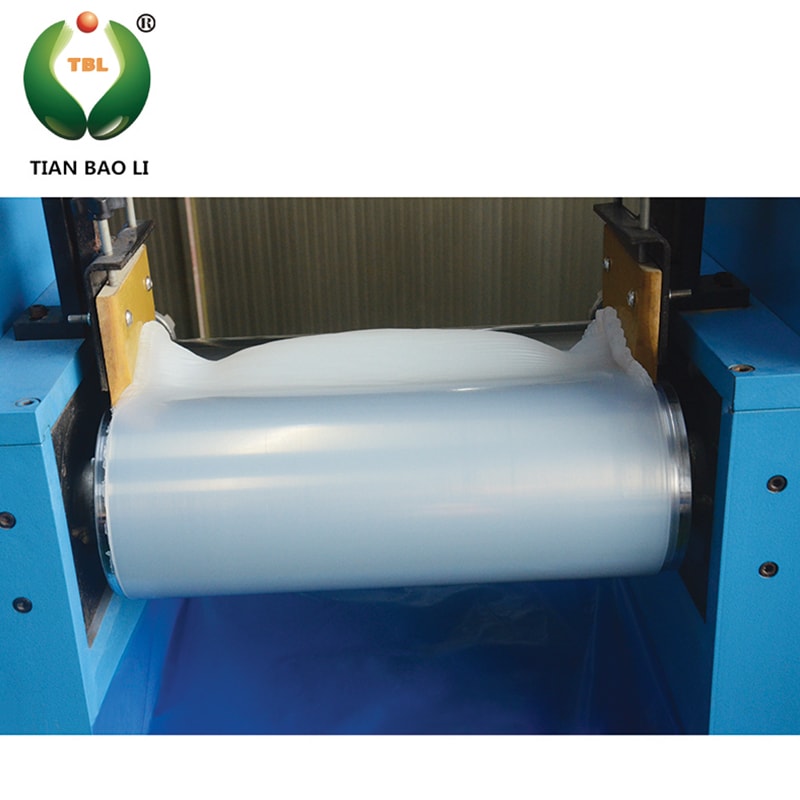

- HTV Silicone Rubber

- High transparent food grade HTV silicone rubber raw material TBL-500 Series

High transparent food grade HTV silicone rubber raw material TBL-500 Series

- Place of Origin: Guangdong, China

- Brand Name: TBL

- Model Number: TBL-500

- Quantity: 1000 Kilogram/Kilograms (Min. Order)

- Support : Sea shipment; Air shipment

- Lead Time:

- Quantity (Kilograms): 1 - 10000>10000

- Est. Time (days): 5 Negotiable

- Payments: This supplier also supports L/C, T/T payments

- Package: 20KG/Carton+Pallet

PRODUCT Description

The hardness range of this series of products is 20-80 ShoreA, with high transparency, good processability, easy

demoulding and other characteristics. Products are generally suitable for all kinds of silicone household items,

miscellaneous items, tableware and baby products.

Color: Translucent.

Application: Sundries; silicone household products; tableware product; mould making product.

Appearance: Colorless Transparent Liquid.

Product name: HTV Silicone Rubber.

Hardness Shore A: 20 - 80.

Features: High transparency,Excellent processing property; Esay to demould

Shelf life: 6 Months.

HS code: 3910000000.

Viscosity: Favorable.

Product Presentation

This product does not use substances prohibited by the RoHS directive, and the requirements for hazardous substances shall be implemented in accordance with the RoHS directive, and relevant third-party certification reports such as RoHS, REACH, and FDA are updated every year.

Travel Release Of Liability

All above suggestions on using are based on our experience. Consumers must conduct their own experiments and analysis to determine whether these products are suitable for the special use of users. In no case shall we be responsible for the end use of the consumer. Every procedure must be adapted to all legal rules and authoritative legislation.

Product Description

The hardness range of this series of products is 20-80 ShoreA, with high transparency, good processability, easy demoulding and other characteristics. Products are generally suitable for all kinds of silicone household items, miscellaneous items, tableware and baby products.

Product Features

High transparency;

Excellent processing property;

Easy to demould;

Pass the certification of ROHS, REACH and FDA.

Product Presentation

This product does not use substances prohibited by the RoHS directive, and the requirements for hazardous substances shall be implemented in accordance with the RoHS directive, and relevant third-party certification reports such as RoHS, REACH, and FDA are updated every year.

Storage And Transportation

20kg carton, lined with plastic film. It needs to be laid flat during transportation to avoid collision, heavy pressure and moisture. It should be stored in a ventilated warehouse with temperature ≤35℃ and humidity ≤65%. The storage period of the product in the above environment is 6 months from the date of production.

Travel Release Of Liability

The above data are typical data for reference only. Advice on the use of our products is based on our experience.

Consumers must conduct their own experiments and analysis to determine whether these products are suitable for the user's particular use. In no event shall we be responsible for the end use of the consumer. Each handler must comply with all legal rules, including authoritative legislation.

|

Product Type |

General Molding Products |

|||||||

|

Product Model |

TBL-520 |

TBL-530 |

TBL-540 |

TBL-550 |

TBL-560 |

TBL-570 |

TBL-580 |

|

|

Appearance |

Visual inspection |

Translucent |

Translucent |

Translucent |

Translucent |

Translucent |

Translucent |

Translucent |

|

Williams Plasticity |

GB/T 12828-2006 |

90 |

110 |

140 |

160 |

190 |

200 |

|

|

Density (g/cm3,25℃) |

GB/T 533-2008 |

1.05 |

1.10 |

1.12 |

1.15 |

1.19 |

1.19 |

1.23 |

|

Linear shrinkage (%) |

GJB 5873-2006 |

3.50 |

3.40 |

3.40 |

3.40 |

3.40 |

3.50 | 3.50 |

|

Hardness (Shore A) |

GB/T 531.1-2008 |

23 |

31 |

40 |

51 |

60 |

71 |

78 |

|

Tensile strength (MPa) |

GB/T 528-2009 |

4.5 |

7.5 |

8.5 |

8.0 |

8.0 |

7.5 |

7.8 |

|

Elongation (%) |

GB/T 528-2009 |

750 |

700 |

650 |

500 |

400 |

250 |

200 |

|

Tear strength (kN/m) |

GB/T 529-2008 |

12 |

16 |

18 |

20 |

22 |

23 |

16 |

|

Resilience (%) |

GB/T 1681-2009 |

70 |

65 |

65 |

60 |

55 |

55 |

|

|

Remarks: 1. The physical data listed in the above table are for reference only. If you need the inspection report of the goods, please contact the sales staff; 2. Vulcanization conditions: 175℃×6min, the addition ratio of vulcanizing agent is 1%, and the main components is 2,5-Dimethyl-2,5-di(tert-butylperoxy)hexane (DHBP). |

||||||||

Silicone rubbers have been developed for a number of uses in the industries. They are useful in applications where they can be applied and molded to meet all the different manufacturing requirements. Since these products have the ability to form into mats, tubes, sheets, etc., it is possible to use them for different purposes. These materials are known for their high resistance to wear and tear, flexibility, chemical resistance, thermal conductivity, etc.

This type of transparent liquid silicone rubber has the ability to maintain its elasticity under extreme heat or cold conditions. Hence it can be used in a number of bake-off processes, hot-mold process, etc. In addition, it can be used in curing chambers, stainless steel cooling chambers, thermal insulating sheets, etc.

This type of rubbers is made from a tough and resilient silicone compound called polyisoprene. These products are extensively used in the automotive and marine industries as they offer excellent resistance to water, flame, alkalis, solvents and chemicals. It also remains unaffected by most of the common chemicals that are found on the surface of many types of vehicles. These products are popularly used in all kinds of vacuum cleaners, generators, pressure washers, air conditioners, generators, power tools, motorcycle tires, industrial lubricants, water pipes and fittings, pumps, etc. Also they can be found in various food and beverage industries.

The clear liquid silicone rubber is available in a large variety of forms such as sheets, balls, beads, etc. They are very easy to cut with standard scissors. As they are generally thick in nature, it is possible to use small electric drills at times. These materials can also be shaped into desired shapes with the help of a hot knife or soldering iron.

Another important aspect of this product is that they do not allow vapor to pass through them. This ensures that the adhesive or glue applied on the surface of transparent liquid silicone does not stick on any sort of liquid substance. Silicone sealants are made of a special thermosetting polymer, which allows a good amount of heat to pass through them. So these materials are really beneficial for those looking to purchase sealants for their products.

Some clear transparent liquid silicone rubber can also be mixed with wax to make an anti-static agent. However, this should be done with care as such kind of mixture may cause damage to some electronic equipments. The price of such liquid seals depends on the thickness of the silicone material and also its chemical composition. The price of pure silicone will definitely be more expensive than that of a mixture of silicone and wax. Also the price of pure liquid silicone will be higher than that of gel or rubber. So if one intends to purchase these kinds of sealants they must take the time to study the pros and cons of different brands and types available in the market.

Related Products

CONTACT US

Foshan Tian Bao Li Silicon Engineering Technology Co., Ltd.

We are always providing our customers with reliable products and considerate services.

If you would like to keep touch with us directly, please go to contact us