- Home

- Product

- Liquid Silicone Rubber

- Excellent Resilience Liquid Silicone Rubber TBL-8100 Series

Excellent Resilience Liquid Silicone Rubber TBL-8100 Series

- Place of Origin: Guangdong, China

- Brand Name: TBL

- Model Number: TBL-8100 Series

- Quantity: 1000 Kilogram/Kilograms (Min. Order)

- Support : Sea shipment; Air shipment

- Lead Time:

- Quantity(Kilograms): 1 - 10000>10000

- Est. Time(days) 5 Negotiable

- Payments: This supplier also supports L/C, T/T payments.

- Package: 20KG/200KG Bucket+Pallet

PRODUCT Description

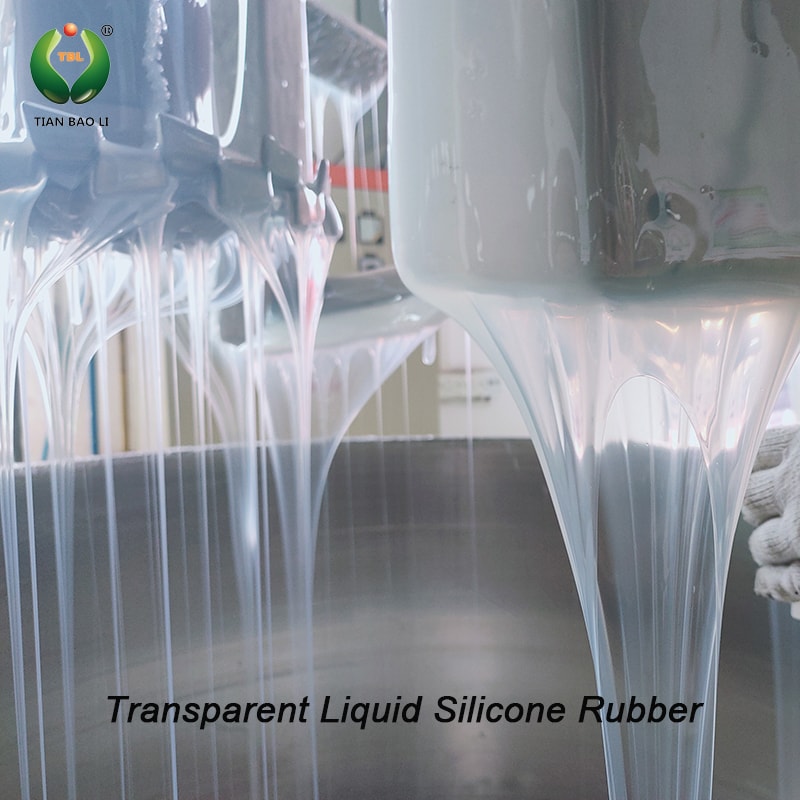

This series product is two-component addition liquid silicone rubber, which has excellent high and low temperature resistance, excellent weather resistance.

It adopts to the liquid injection molding process technology and can be widely used in kitchenware, industrial seals, silicone gasket, adult products and other

industries.

Application: kitchenware, industrial seals, silicone gasket, adult products and other

Appearance: Translucent.Liquid.

Product name: Liquid Silicone Rubber.

Hardness Shore A: 20-70.

Features: High strength, Excellent weather resistance, Aging resistance, Rapid prototyping, good flowability.

Shelf life: 12 Months.

HS code: 3910000000.

Viscosity: Favorable.

Product Presentation

This product doesn't use substances prohibited by ROHS instructions, and hazardous substances shall be implemented according to ROHS instructions. The third party certification reports such as ROHS, REACH and FDA will be updated every year.

Travel Release Of Liability

The information contained herein is offered in good faith and is believed to be accurate. However, because conditions and methods of use of our products are beyond our control, this information should not be used in substitution for customer’s tests to ensure our products are safe, effective, and fully satisfactory for its intended end use. Suggestions of use shall not be taken as inducements to infringe any patents.

Tian Bao Li’s sole warranty is that our products will meet the sales specifications in effect at the time of shipment.

Your exclusive remedy for breach of such warranty is limited to refund of purchase price or replacement of any product shown to be other than as warranted.

To the fullest extent permitted by applicable law, Tian Bao Li specifically disclaims any other express or implied warranty of fitness for a particular purpose or merchantability.

Tian Bao Li disclaims liability for any incidental or consequential damages.

Product Features

High strength

Excellent weather resistance

Aging resistance

Rapid prototyping

How To Use

1. Suggest that the consumer use the liquid injection molding machine to inject into the mold and manufacture products.

2. The two components of A and B must be completely mixed by machine according to the weight or volume ratio of 1:1. The vulcanization time is determined by the molding temperature. At high temperature conditions, a short time is required for product forming. If the silicone product is thick and large, it takes longer time to mold. After vulcanization, the mold can be disassembled.

3. If the machine is shut down for a long time (more than two days), either inject component A or component B into the mixing section alone. Or remove the static mixer of the injection molding machine immediately, seal and store it in a low temperature (< 1℃) environment, or clean up the remaining rubber.

Packaging, Storage and Caution

1. This series of product is packed in 20 kg/plastic straight pail or 200 kg/metal drum, with plastic liners.

2. Products should be stored in sealed condition, kept it in a cool place and avoid rain and sun exposure.

3. This series of products are non-dangerous goods. The valid period is 1 year. If the products exceed the storage life, it can be re-tested to prove the curing speed is acceptable, if so, it can be used.

4.To prevent cure inhibition, try to avoid contact with tin compound (most condensation silicone contain tin compound catalyst) amines, sulfur and phosphorus compounds and some metal salts.

5. In this series, component A contains catalyst and component B contains cross-linking agent. When products from different manufacturers are used, tests shall be carried out to avoid cross-linking reaction.

|

Item & Model |

TBL-8120 |

TBL-8130 |

TBL-8140 |

TBL-8150 |

TBL-8160 |

TBL-8170 |

|

Proportion |

1:1 |

1:1 |

1:1 |

1:1 |

1:1 |

1:1 |

|

Appearance |

Translucent |

Translucent |

Translucent |

Translucent |

Translucent |

Translucent |

|

Viscosity |

30×10 4 |

50×10 4 |

80×10 4 |

90×10 4 |

100×10 4 |

120×10 4 |

|

Hardness/Shore A |

18-22 |

28-32 |

38-42 |

48-52 |

58-62 |

66-72 |

|

Tensile Strength/MPa |

≧4.0 |

≧5.0 |

≧6.0 |

≧7.0 |

≧7.5 |

≧7.0 |

|

Elongation/% |

≧450 |

≧400 |

≧400 |

≧400 |

≧260 |

≧150 |

|

Tear Strength/kN/m |

≧6 |

≧10 |

≧12 |

≧15 |

≧20 |

≧15 |

|

|

1.10 |

1.10 |

1.11 |

1.12 |

1.13 |

1.14 |

|

Above data are for reference only. Factory quality inspection report shall prevail for latest testing standard and data. |

||||||

The price of high transparent liquid silicone rubber is rather high nowadays but its much impact on the environment isn't visible at all. Silicone is an environmentally friendly raw material which is now being widely used for manufacturing many other products like rubber gloves, car tyres, luggage handles, toys, and other uses. But the best thing about this new material is that it has many potential applications in our daily lives. It can be used as a lubricant for many industrial mechanical parts because it's quite strong and elastic yet durable too.

Silicone has a lot of unique qualities which make it the ideal choice for manufacturers to use in many industries. Its high transparency level makes it possible to see the rubber beneath the surface without any dust. This makes it an excellent material for use in food grade packaging. Since it's clear to the eye, it also enables manufacturers to produce as many coloured rolls as possible with high quality and consistent colours.

In addition, high transparent liquid silicone rubber can be used in the production of baby bottles, infant bodysuits, nightwear, undergarments, pharmaceuticals, industrial rubber, and medical silicone products. This versatile and strong material can be moulded into almost any shape or form, from poly sticks to polyurethane pellets, flat sheets to tubes, and even hollow tubes for candle caps and water bottles. This means it's possible to find all sorts of different products that feature this amazing material.

As well as all these potential uses there are also some specific reasons why it's so useful in the manufacturing industry. One of its most useful properties is its high tear strength and rigidity. This makes it very good at resisting damage from impact and heat. It's also been found to be ideal for food grade packaging. When combined with other silicone resins, high transparent liquid silicone rubber offers a very cost effective way of sealing, packing and storing of all kinds of goods.

One example is the manufacturing of tear-resistant food grade silicone wristbands. Because it's so hard, it's very important to use a high transparent liquid silicone rubber that's flexible enough to create a tight seal around the product yet durable enough to withstand high pressures and wear and tear. To create this seal, the material needs to be rolled onto a heat-rolling machine, which melts it into a solid block that's then fed into the moulds' chamber. Once hardened, it's then fed into the moulds where the liquid rubber is poured into the moulds' walls, secured by high pressure and high temperatures. The result is a high quality and effective plastic wristband with a printed or engraved logo to make your promotional campaign unique.

Silicone has been a popular material for high quality waterproofing and tear resistance applications, but as yet there hasn't been any effort to standardise the manufacturing process for all different grades of transparent silicon rubber. As an alternative to high quality resins and rubbers it can be used in a more flexible production process that combines flexibility with high quality and durability. This allows flexibility when designing campaigns and getting creative with your branding. if any interests in our products, please pay your visit to our website: https://www.tblsilicone.com

Related Products

CONTACT US

Foshan Tian Bao Li Silicon Engineering Technology Co., Ltd.

We are always providing our customers with reliable products and considerate services.

If you would like to keep touch with us directly, please go to contact us